As colder weather approaches, it’s important to make sure your spray foam rig–and everything inside it–is properly prepared. Cold temperatures can impact chemical performance, equipment efficiency, and overall jobsite productivity. When the temperatures drop, even the most experienced applicators can face inconsistent spray patterns, poor yields, and equipment strain if the rig isn’t maintained and prepped correctly.

At Accufoam, we’ve seen how the shift into winter can challenge even seasoned contractors. With a little preparation and some key equipment checks, you can ensure your rig performs reliably all season long. Below are a few essential maintenance steps and conditioning tips to keep your system running smoothly through the colder months.

Material Conditioning

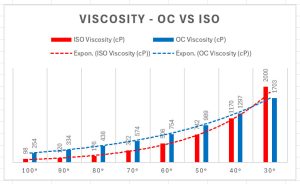

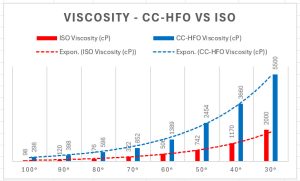

Your spray foam components–ISO (A-side) and Resin (B-side)–are sensitive to temperature. Maintaining drum temperatures in the range of 70°–90°F is critical for consistent viscosity and spray quality, especially for proportioners with smaller preheaters that can struggle to compensate for cold materials.

Here’s a look at some of the most effective tools and methods for maintaining those drum temperatures:

- Drum Band Heaters:

These are excellent for applying direct, uniform heat around the lower portion of the drum, where your transfer pump draws material. They’re ideal for gradually warming the material and preventing cold spots that can affect proportioning.

- Drum Blanket Heaters:

These offer full-surface coverage to maintain temperature across the entire drum. While they’re not strong enough to heat a cold drum from scratch quickly, they’re great for preventing heat loss once your materials are already at the correct temperature.

- Barrel Blazer Hot Plates:

Designed for bottom-up heating, Barrel Blazers are effective in cold storage environments where drums sit directly on the floor. They distribute heat evenly and feature built-in thermostats for accurate temperature control. Additionally, good for keeping the lower portion of drum warm where the transfer pump is drawing material from.

- Diesel Cabin Heaters:

These are a favorite among contractors who want to keep their rigs warm throughout the day and night. Diesel heaters can be ducted to direct warm air toward the drums, equipment, and even the operator area, keeping both materials and crew comfortable. Additionally, because these heaters can run off of 12V batteries or AC power souces, they are preferred for keeping materials and rigs warm 24/7.

- Electric Space Heaters:

While not the first choice, they can serve as a backup or supplemental heat source. However, use caution: electric heaters carry a higher risk of fire and should be used only with appropriate clearances and safety measures.

Before operating any of these devices, inspect all heaters for damage, including frayed cords, cracked insulation, or faulty thermostats. Preventative checks not only ensure safety but also keep your rig functioning efficiently when temperatures drop.

The above graphs show how temperature directly affects material viscosity. This reminds us that cold materials mean thicker, slower flow, which equals more strain on the proportioner and more variances in feed and spray pressure.

Maintaining Rig Interior Temperature

Maintaining the right interior temperature inside your rig is equally important. A warm, stable environment prevents viscosity changes, crystallization, and premature wear on pumps, hoses, and proportioners.

- Electric or Diesel Heaters in the Rig:

Keeping a steady internal temperature protects both your materials and your crew. Many contractors prefer diesel heaters for their reliability and heat output, especially in larger trailers.

- Insulate the Rig Interior:

If your rig isn’t already insulated, adding insulation to the walls, doors, and flooring is one of the best ways to retain heat. It not only reduces energy use but also ensures that heat from your equipment and heaters stays where it’s needed most.

Always follow proper ventilation and fire safety procedures, particularly with fuel-burning heaters. Check for adequate airflow and confirm all exhaust outlets are unobstructed before operation.

Hose Heat and Insulation

Maintaining consistent hose temperature is critical for steady material flow and even spray patterns. Even if your drums and rig are properly conditioned, heat loss through uninsulated or malfunctioning hoses can cause major issues.

- Calibrate Hose Heat:

Verify that your proportioner’s hose heat system is accurately calibrated. Some proportioners require periodic recalibration to ensure temperature sensors are reading correctly. A small variance in hose temperature can make a big difference in spray quality.

- Insulate Spray Hoses:

Keep hoses wrapped and insulated to minimize heat loss, especially when spraying outdoors or in unheated buildings. When hoses rest on snow, ice, or cold concrete, they lose heat rapidly, resulting in poor atomization and uneven spray patterns.

- Inspect Electrical Connections:

Check all temperature sensors, connectors, and cable terminations for corrosion, looseness, or damage. Clean and repair anything that could compromise consistent temperature readings or cause intermittent heating.

Long-Term Storage Considerations

If your rig will be idle for several weeks or months during the winter, it’s essential to prepare it properly to avoid costly damage. The Spray Polyurethane Foam Alliance (SPFA) Technical Tip G-9 provides an excellent reference for Long-Term Rig Shutdown Procedures.

Key steps include:

- Flushing and cleaning proportioners, transfer pumps, and spray guns to remove residual material.

- Draining and protecting lines against moisture and crystallization.

- Storing materials within their recommended temperature range (typically 70°F minimum).

- Disconnecting and safely storing electrical cords and hoses to prevent damage or corrosion.

Taking the time to complete these steps will help prevent crystallization, hardening, or degradation of your spray system components, ensuring your equipment is ready to perform when the season turns warm again.

Final Thoughts

Preparing your rig for winter doesn’t have to be complicated, but it does require attention to detail. The time you spend inspecting, insulating, and calibrating now can save you downtime, wasted material, and frustration later.

At Accufoam, we’re committed to helping contractors get the most from their equipment in every season. If you have questions about rig setup, cold-weather material handling, or optimizing your spray performance, our Technical Service Team is here to help.

Cold weather might slow things down outside, but with the right preparation, your rig can keep performing at its best, job after job.