When applicators install SPF (spray polyurethane foam) foam insulation in a residential attic, there’s an increased risk of incorrectly sealing the space. Particularly in attics designed to be vented (as many residential attics are).

Here’s the problem:

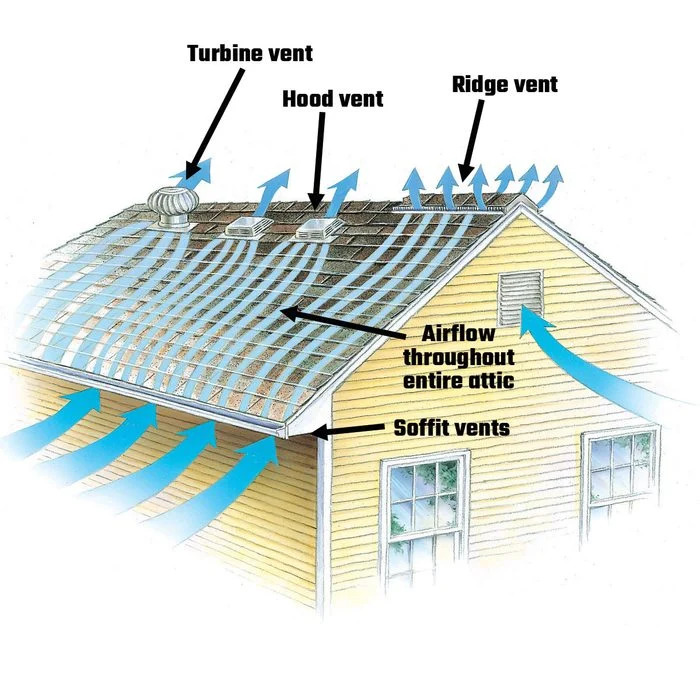

Typically, by design, attics are designed to encourage airflow. Often, this airflow is designed to enter through the soffit area under the overhang of a building’s roof. Hot, moist air in the attic is then circulated and vented (thanks to positive airflow outside the roof and intake from the soffits) and ultimately will exit through hood, ridge, or turbine vents near the apex of the roof. Soffits are any finish material covering the underside of the roof where the roof extends beyond the building walls.

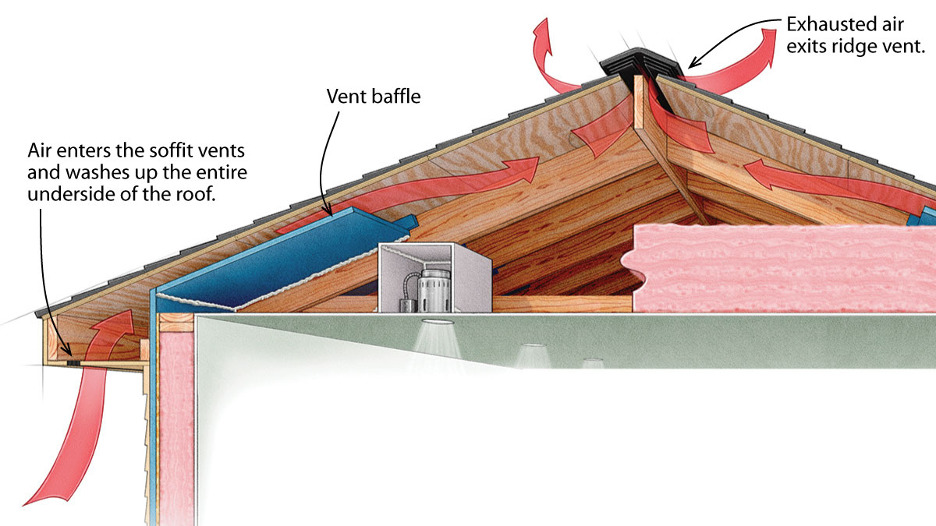

Sprayfoam-insulated attics take a ventilated space (typical attics) and convert them into a conditioned, unventilated space (by the code, an Unvented Attic Assembly). By definition, to be an unventilated space, the attic must be sealed off from airflow. Spray foam applicators must understand this process and ensure that this sealing is performed correctly. The complication (especially in “retrofit” residential applications) is that soffit areas are often exposed to the outside environment with no backing material or substrate to adhere to. As seen in the picture below, the soffit material is usually attached under the overhang of the joists for aesthetic purposes but is otherwise open to the attic cavity. This cavity can be just a few inches but can also extend to multiple feet in some instances. Depending on product selection and depth, “filling” the gap with spray foam is not practical or recommended.

If you’ve been on the job for some time, then you’ll know the standard option for spray foam applicators is to make spray foam “pancakes” or use cardboard, fiberglass or other production option to stuff the eave and solve this problem.

Spray foam applicators can use cardboard baffles to provide a sprayable backing at the eave, but sometimes this process is done incorrectly. The cardboard baffles do provide a suitable substrate for spray foam insulation. The critical component of the blocking install is that the blocking be just outside of the building envelope, allowing the spray foam to totally seal off the space and make for a 100% unvented attic assembly and conditioned attic space.

With the backing (cardboard, fiberglass, foam pancake or other option) just outside the building envelope and mostly blocking the soffit/eave space, spray foam can be applied to totally seal of the attic from the soffit vents and when applied correctly, make for a totally conditioned attic space.