What are the lifelong Energy Savings of Spray Foam Insulation?

A Life Cycle Analysis of Spray Foam Insulation

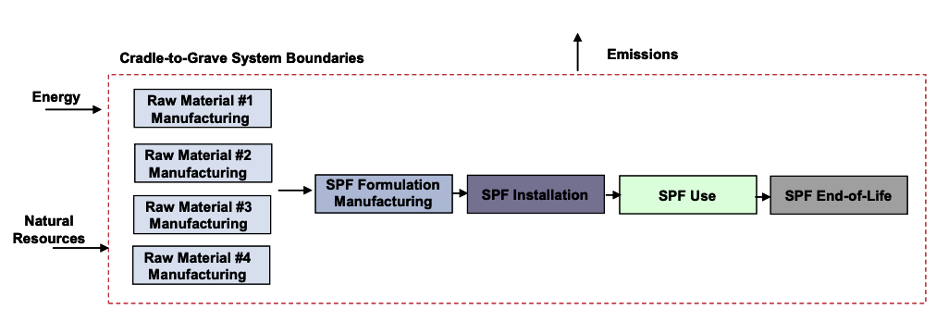

What is the spray foam life cycle? What are the lifelong Energy Savings of Spray Foam Insulation? To fully understand the complete benefits of spray foam insulation, you must look at all stages of a product’s life, from cradle-to-grave. Across the building and construction industries, this is referred to as a Life Cycle Analysis (LCA).

You’ve heard it before…the promises about spray foam insulation and spray polyurethane foam (SPF). It has higher R-values, it doesn’t sag over time, and it doesn’t experience convective loss. There are certainly plenty of benefits of using spray foam over fiberglass and other conventional alternatives.

Typically, many benefits touted around SPF focus on the energy-saving attributes. But energy savings is only one portion of the environmental impact and benefit of spray polyurethane foam.

LCAs give a holistic picture of the environmental impacts (both positive and negative) of a product from its manufacture to the end of its life and disposal.

The figure below gives you a good idea of what “cradle-to-grave” life cycle takes into account.

Figure 1: (Above) The factors that go into a “cradle-to-grave” Life Cycle Analysis (LCA) for Spray Polyurethane Foam Insulation

SPRAYFOAM INSULATION IS BETTER FOR THE ENVIRONMENT IN THE LONG RUN

Want the short version without reading further? Spray Foam Insulation (spray polyurethane foam) is better for the environment in the long run. SPF is better because it delivers more energy savings for longer, even with detrimental impacts on the environment during installation.

Knowing the environmental impact of a product can help you win more bids as a contractor, most contractors in the industry aren’t touting their materials’ life-cycle analysis. However, knowing where the energy savings come from will make you more knowledgeable and more equipped to beat out the conventional competition. Understanding the materials you’re applying and their environmental impact can also help you win coveted government contracts and large commercial jobs.

This is especially true for insulation materials. Insulation materials carry an initial environmental impact/cost from manufacturing, transportation, and installation. But the materials then have a positive environmental impact in the form of energy savings over their lifespan.

- There is a more significant initial environmental impact to be paid with SPF.

- Because of fiberglass’s lower initial environmental impact investment, the Environmental Recovery Period (Environmental Breakeven point) is shorter with fiberglass.

- Over the life of the building, Spray Foam will save more carbon emissions than the equivalent R-value (IECC compliant) of fiberglass.

Reference: Spray Foam, Take Your Rightful Place – The Importance of Life Cycle Analysis. Harris, Tom.

https://www.sprayfoamprofessional-digital.com/spfq/0421_winter_2021/

Initially, there is a more significant environmental impact for SPF insulation. However, over the lifespan of the building, spray foam insulation will positively impact the environment. That’s thanks to spray foam insulation’s air impermeability, lack of sag over time, and lack of convective loss (which fiberglass insulation does experience over time). Further, the initial energy savings of spray foam insulation can be felt immediately compared to fiberglass insulation.

The green building trend isn’t going away and only continues to expand as individuals and businesses look to leverage environmentally friendly building practices to save on skyrocketing energy costs.